Land Rover Lightweight

23-KB-26

Infra-red Working

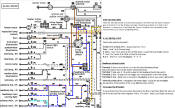

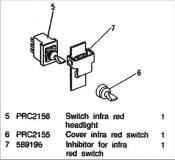

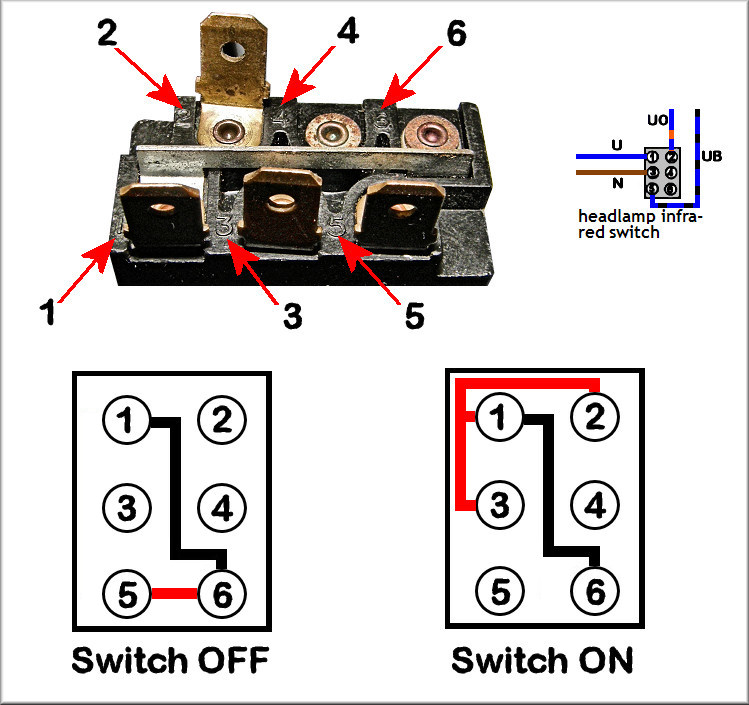

| The Infra-red setup in a British Military Vehicle was designed so that with the throw of one switch, ALL lights other than the dipped Headlights were disabled. The Dipped Headlights had a cover that could be placed over them to ensure that only Infrared light was displayed. The driver would then don Infrared goggles to enable him to see. This set up was very complicated and you only have to look at the differences in the circuit diagrams between IR and non-IR vehicles to see the complexity added. There were problems with the reliability of the IR Switch and the IR Relay and Wiring had a habit of burning out! |

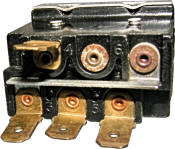

| In the OFF position

terminals 1 and 5 are connected. Terminal 1 carries the feed

to the Dipped Headlights and terminal 3 has the feed from the 6-way

Light switch i.e. the Dipped Headlamps are controlled by the light

switch. In the ON position the Dipped Headlamp feed (terminal1) is broken away from the Light Switch (terminal 5) and is now fed from the power feed to the IR Switch (terminal 3) This power feed is now also connected to terminal 2 which feeds the IR Relays. These switches were infamous for their failure rate. If the switch failed you basically could lose all the lights. When I acquired my switch recently, the contact between terminals 1 and 5 in the OFF position was lost. This would mean in the normal working condition the feed to the Dipped Headlights from the 6-way Light Switch would be missing i.e. no Dipped Headlights. In my late 1983 Series 3 Lightweight the switch was removed and wired out, probably from manufacture. |

Click on image for full size Photo