Land Rover Lightweight

23-KB-26

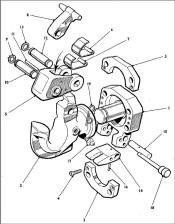

NATO Hitch

Click on images for full size Photo

|

|

|

|

|

|

|

||

|

||

|

|

|

| Jeff Case's photos of his stripped down pintle | ||

|

||

The top of the hitch must be locked down using the split pin, R clip or nappy pin depending on age.

B Dixon-Bate

Dixon-Bate current towing pintle

|

"Towing Pintles are hooks designed to rotate up

to 360 degrees to allow the trailer to rotate independently of the

towing vehicle when off-road. This is particularly important when

towing at high speed, which is often a military requirement. The above statement is from the Dixon-Bate Web Site. However, the following comment has been received from John Hughes on the EMLRA Forum. "The pintle must be locked or set to rotate

depending on whether the trailer hitch rotates, at all times when

towing a military trailer one part of the hitch assembly must

rotate. This means the entire train will not tip over if the trailer

skips if you get a blow out or fall in a hole. I've seen a 110

pulled over by an empty widetrack trailer bouncing out of a pot

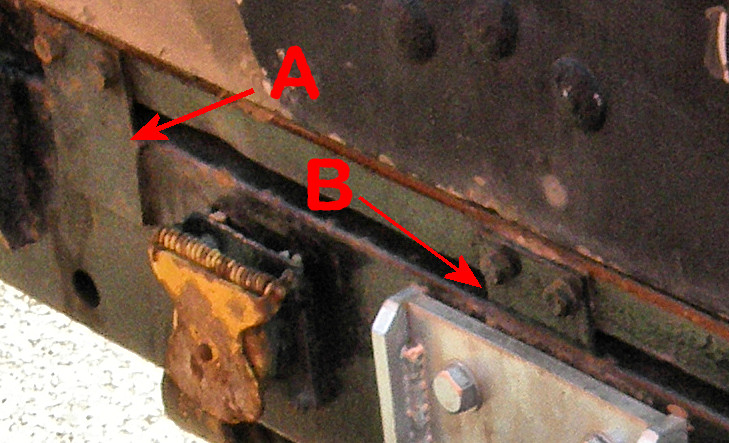

hole." The rear crossmember on the Lightweight is in fact of a very 'lightweight' construction. It is not the same as the civilian equivalent model. Care has to be taken when mounting a towing hitch or pintle, as the forces applied by a 'trailer' can distort the crossmember. Hence, for example, when mounting a NATO Hitch, two spreader plates of suitable size with the appropriate holes are necessary to stiffen and distribute the applied forces. One between the hitch and the crossmember (A) and the other behind the crossmember between the crossmember and the washers/nuts (B). |

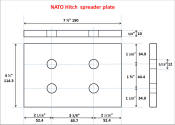

crossmember spreader plate (B) part No. 531447

courtesy 'FULLTILT'

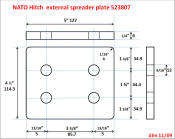

External spreader plate (A)

523807 and packing plate

(A1) 531448 for early rear crossmembers

| For the new arrangement, later crossmember, the body (tub) centre support was re-designed so that the thin plate (A1) with clearance cut-out was eliminated and just the spreader plate used. |

| Original centre tub mount was the same as the others, a flat plate welded to the member (A). On later crossmembers it was changed to an angle plate welded to the top of the member (B), hence no need for the packing plate. |

courtesy 'FULLTILT'

My Lightweight

| My Lightweight has no spreader plate for the Washers/Nuts and the Drop Plate for the hitch has two bracing flanges at the edges which means that the face of the plate does not contact the crossmember and spread the 'load'. When the rear crossmember was replaced, by the correct military one, the angle iron braces were not replaced. See below for the correct bracing. |